DEFORMATION

OF PORES IN IONIC CRYSTALLINE MATERIALS UNDER HEATING BY A LINEARLY POLARIZED

MICROWAVE FIELD

K.I. Rybakov(1),

V.E. Semenov(1), G. Link(2),

M. Thumm(2)

(1)

Institute of Applied Physics, Russian Academy of

Sciences, Nizhny Novgorod, Russia

(2) Forschungszentrum

Karlsruhe, Institute for Pulsed Power and Microwave Technology, Karlsruhe,

Germany

ABSTRACT

Elongation and preferred orientation of pores in zirconia ceramics has been observed experimentally upon heating by a linearly polarized microwave field but not upon conventional heating. The effect is explained by the ponderomotive effect of the microwave electromagnetic field at the pore surface. The effect is pronounced most in materials with sufficient microwave absorptivity. This is a direct experimental proof of the significance of the ponderomotive microwave non-thermal effect on mass transport in solids.

KEYWORDS: zirconia, pore structure, ponderomotive effect.

INTRODUCTION

The problem of non-thermal effects has become one of the most controversial issues in the recent literature on microwave processing of materials. Although many manifestations of microwave mass transport enhancement have been observed experimentally, the phenomenon still lacks comprehensive characterization and fundamental physical understanding.

High-frequency electromagnetic fields have been shown to influence mass and charge transport in ionic crystalline bodies due to the so-called ponderomotive effect [1]. The oscillating vacancy currents driven by the high-frequency field are perturbed near structural nonuniformities such as grain boundaries, pores, or external surface of the crystal. The vacancy space charge induced due to these perturbations interacts with the field in a non-linear way, which causes rectification of vacancy currents and accumulation or depletion of vacancies near the surface. The resulting slow neutral vacancy flows lead to mass transport in the crystalline body.

The objective of this paper is to provide a direct experimental evidence of the validity of the model by comparing its prediction with experimental observation of mass transport phenomena in ionic crystalline materials. The deformation of an ionic crystalline body induced by the ponderomotive effect was considered in detail in [2] for the case of a spherical crystalline grain. It was predicted that under the action of polarized microwave radiation a spherical grain would elongate across the electric field vector. However, these results have long been remaining unconfirmed experimentally, because it would be diffucult to isolate a separate micron-sized grain and observe its evolution in intense microwave field. A pore in an ionic crystalline material is a much more suitable experimental object.

EXPERIMENTAL

Zirconia ceramic is known for its high ionic conductivity especially at temperatures as high as they are necessary for sintering. Therefore a significant interaction with microwave fields can be expected. For experiments 3 mol. % yttria stabilized zirconia (TZ3YS) from Tosoh Company, Japan was used. The mean grain size of the powder material was 27 nm. The motivation in using a nanosized powder was to reduce the influence of superimposed thermal effects. Due to the higher sintering activity of nanopowders compared to their coarse counterparts, reduced sintering temperatures can be used and thus thermally activated driving forces might be smaller.

To eliminate potential anisotropic strains or stresses within the green bodies that may influence the pore structure evolution during sintering, samples were fabricated by the electrophoretic deposition technique (EPD) [3] at the University of Saarbrücken, Germany. For an optimal shaping with EPD a deaggregation and dispersion of the powders into an agglomerate-free suspension with a high solid loading was realized. The green bodies produced by EPD were dried for 24 h at room temperature and then in a drying chamber at 120 °C for another 24 h. The samples had a relative green density of approximately 53 % of the theoretical density (TD) which was 6.07 g/cm3. The characterization by Hg-porosimetry revealed a homogenous and monomodal pore size distribution with a mean pore size of 45 nm.

The so produced samples of irregular shape with a characteristic length of up to 10 mm were sintered in the maximum of the linearly polarized microwave field of a TE103 waveguide applicator at a 2.45 GHz. The utilized waveguide had a square cross section of 8 x 8 cm2 [4]. The microwave power was launched via a standard WR340 waveguide and an adequate taper, with vertical polarization of the electric field.

To avoid temperature gradients during the sintering process, which may result in inhomogeneous sintering as well, the specimens were placed into a zirconia crucible, according to the thermal barrier wall concept of Sato et al. [5]. The crucible itself was surrounded by mullite ceramic fiberboards for thermal insulation. The sintering process was controlled using a temperature signal from a pyrometer. Typically a constant heating rate of 30 K/min was applied to reach the final sintering temperature. Depending on the sintering temperature, the soak time was adjusted so that the achieved sintered density was in the range from 95 %TD to 99 %TD. This allowed having a microstructure with closed porosity and therefore mainly isolated pores for the subsequent microstructure analysis.

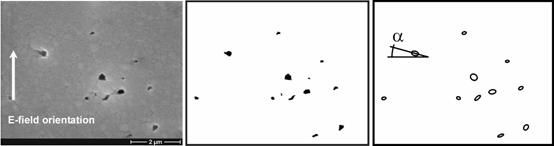

After sintering, samples with adequate density for the

microstructure analysis were cut and polished and thermally etched at 1100 °C

for about one hour in a conventional furnace. Then a number of micrographs

showing isolated pores were sampled using a scanning electron microscope (SEM).

The samples were oriented within the SEM so that the electric field as present

during microwave sintering could be indicated in vertical direction. Then the

images were converted to binary mode and analysed with ImageJ software

(National Institutes of Health, USA) (see Fig. 1) by fitting an equivalent ellipse to each pore

and to determine the angle of the long axis with a horizontal line,

perpendicular to the direction of the applied electric field.

Fig. 1: ImageJ procedure: SEM picture (a), conversion into binary image through definition of threshold value (b), approximation by ellipses (c).

RESULTS AND DISCUSSION

The results of image analysis were plotted in histograms showing the number of pores found in different equidistant intervals of angle (see Fig. 2). To reach sufficient statistical significance this method was only applied when the number of detectable pores was larger than 200. The left histogram in Fig. 2 gives the result obtained with a microwave sintered TZ3YS sample. Using a sintering temperature of 1270 °C for 24 hours resulted in a density of 5.81 g/cm3. About 250 pores have been evaluated for this sample. The right graph demonstrates an equivalent result obtained for a sample conventionally sintered at 1400 °C for one hour. With a similar density of 5.84 g/cm3 this sample allowed to evaluate about 300 pores.

Fig. 2: Histograms showing orientation of pores in the cases of microwave (MWS) and conventionally (CS) sintered zirconia ceramics.

In the case of microwave sintering there is a distinct increase in the number of pores oriented perpendicular to the applied electric field (which corresponds to an angle near 0° or 180°) and a significant decrease in pores oriented parallel to it (angle about 90°). The average ratio of pore dimensions perpendicular / parallel to the electric field vector, determined using the same software, was found to be about 1.22 for the microwave sintered sample. This suggests that the pores are elongated across the electric field vector. By contrast, in case of conventional sintering within the accuracy of this method the angular distribution of the pore orientation was even.

The theoretical model that explains the pore elongation process is described in detail in [6]. Based on the results obtained earlier for a spherical grain [1, 2], it can be shown that the velocity of pore surface normal displacement due to the averaged ponderomotive action of the microwave electric field is

, (1)

, (1)

where D = 2 D- D+

/ (D- + D+), D- and D+

are the diffusion coefficients of negative and positive vacancies,

respectively, ![]() is the vacancy volume,

E0 is the amplitude of the uniform electric field within the

crystalline solid away from the pore, R

is pore radius,

is the vacancy volume,

E0 is the amplitude of the uniform electric field within the

crystalline solid away from the pore, R

is pore radius, ![]() is angular coordinate

counted from the E-field vector direction, and

is angular coordinate

counted from the E-field vector direction, and ![]() is complex dielectric

permittivity of the material, in which the imaginary part is determined by the vacancy

conductivity

is complex dielectric

permittivity of the material, in which the imaginary part is determined by the vacancy

conductivity ![]() :

: ![]() , where N is

vacancy concentration, and e is

vacancy charge.

, where N is

vacancy concentration, and e is

vacancy charge.

Since the direction of the normal

was assumed to be from the bulk to the pore surface, the result (1) means that

the ponderomotive effect leads to the uniaxial compression of the pore along

the electric field vector. In a realistic solid, this pore compression competes

with capillary stresses which tend to sustain the spherical shape of the pore.

As a result of this competition, the pores will reach a certain extent of uniaxial

compression along the electric field vector, which will depend on the intensity

of the electric field and other factors that influence the ponderomotive

effect. In particular, it follows from Eq. (1) that the effect increases with

an increase in ![]() , which means that it should be more pronounced in ionic

crystalline solids with sufficient microwave absorption. The effect reaches

maximum strength when

, which means that it should be more pronounced in ionic

crystalline solids with sufficient microwave absorption. The effect reaches

maximum strength when ![]() .

.

However, even if the microwave absorptivity in the

bulk of an ionic crystalline material is insignificant for the ponderomotive

effect described above to occur, the effect may be locally enhanced in the vicinity

of the pores due to the existence of amorphized layers surrounding the pores in

which vacancy diffusivity is much higher than in the bulk. The influence of the

amorphized layer can be accounted in the above solution [2, 6]. If ![]() , where

, where ![]() is the vacancy

diffusivity in the amorphized layer (at r = R) and

is the vacancy

diffusivity in the amorphized layer (at r = R) and ![]() is the bulk

diffusivity far from the pore, then the final result is

is the bulk

diffusivity far from the pore, then the final result is

, (2)

, (2)

where ![]() is complex dielectric

permittivity in the bulk,

is complex dielectric

permittivity in the bulk, ![]() , and a is the

amorphized layer thickness.

, and a is the

amorphized layer thickness.

It can be seen that the enhanced diffusivity in the

layer results in a greater efficiency of the mass transport in the layer.

Comparing the calculated results (1) and (2), it can be seen that the maximum

velocity of pore surface displacement increases by a factor of about DR

/ Db compared to the case of a uniform solid with no

amorphized layer. Even more importantly, the result (2) shows that the

ponderomotive effect leading to a uniaxial compression of the pore may reach

its maximum strength even when microwave absorption in the bulk of the material

is low, ![]() ; it is only necessary that the absorptivity in the

amorphized layer is significant,

; it is only necessary that the absorptivity in the

amorphized layer is significant, ![]() .

.

According to the quantitative estimates discussed in [1, 2], the ponderomotive effect can be of sufficient strength to manifest itself in ionic crystalline materials under realistic experimental conditions. In general, as follows from the analysis presented above, the effect should be more pronounced in materials with more significant microwave absorptivity.

ACKNOWLEDGEMENT

Partial

support of this research by INTAS (grant # 03-51-5345) is acknowledged.

REFERENCES

1. K.I. Rybakov and V.E. Semenov, Phys. Rev. B 49, 64 (1994).

2. K.I. Rybakov and V.E. Semenov, Phys. Rev. B 52, 3030 (1995).

3. J. Tabellion and R. Clasen, J. Mater. Sci. 39, 803 (2004).

4. A. Möbius, M. Mühleisen, Patent DE-PS 10 114 022 (June 3, 2002).

5. M. Sato et al., Ceram. Trans. 111, 277 (2001).

6. K.I. Rybakov, V.E. Semenov, G. Link, and M. Thumm, J. Appl. Phys. 101, 084915 (2007).