Application of

magnetic micro- and nanoadsorbents in water- and biotechnology – A multiscale

optimization problem

Prof. Dr.-Ing. Matthias Franzreb, Institute of

Functional Interfaces, Karlsruhe Institute of Technology, Herrmann-von-Helmholtz

Platz 1, D-76344 Eggenstein-Leopoldshafen, Germany

E-mail:

matthias.franzreb@kit.edu

Magnetic separations are known for their large scale use in classical

industrial areas such as mineral processing or the steel industry. In addition,

the use of functionalized magnetic micro particles, so-called magnetic beads,

for the isolation and purification of cells, nucleic acids or proteins is

common practice in bioanalytical and biomedical applications. In recent years,

there has been an increasing interest in the combination of these two

techniques in order to achieve large scale separations of toxic water

ingredients but also high value biomolecules. However,

neither the classical separators, nor magnetic beads developed for analytical

puposes are directly suitable for this task, and adopting the process for chemical

and biotechnological applications will be a multiscale, multidisciplinary task.

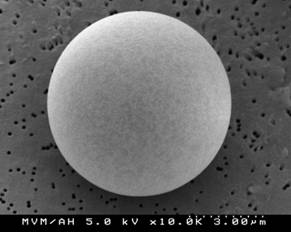

The process development starts at the nanometer level by synthesizing

superparamagnetic nanoparticles with surface coatings preventing them from

agglomeration. The nanoparticles will be encapsulated in polymeric micro beads manufactured

by e.g. emulsion polymerisation. In order to separate the resulting magnetic

beads macroscopic separators will be needed, which are specially designed for

the application in mind. Finally, the complete process must be understood and

optimised. This optimisation can not be done by looking independently at the

described steps of different scale and complexity. As an example, very small

magnetic beads will have superior binding capacities but will be difficult to

separate.

The presentation addresses these multiscale aspects and gives examples of

the current state of applying magnetic sorbents in different areas of water-

and biotechnology.